Why Maintenance Is Important For Marine Boat Hardware

Marine Boat Hardware is one of the most important elements that make a boat’s operation safe and smooth. It is very necessary to maintain the safety of the sailors and crew as well as all the passengers .

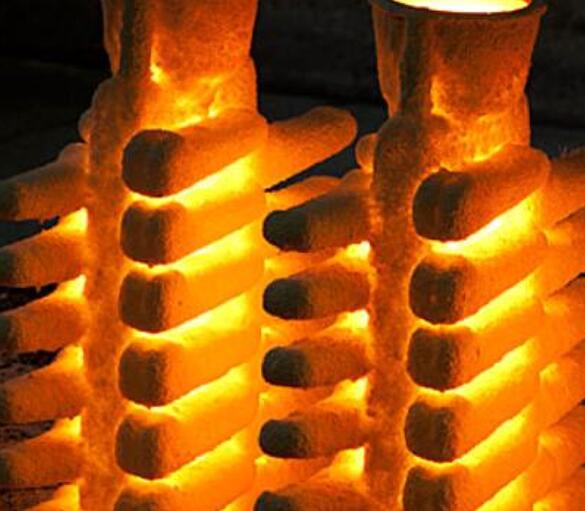

If the marine engine fails to work, the vessel’s navigation system may not function properly or can even become damaged. To prevent any damage to the marine vessel, one has to check the boat’s marine boat hardware regularly. The marine engine has to have proper seals and gaskets, the boat’s motor and steering mechanism, its mast and rigging, the sails, all of which need to be replaced as needed to ensure safe sailing.

The marine navigation system also needs to be checked from time to time so that there are no malfunctions with the boat’s engines, sensors, radio or other equipment. In addition, it is essential to check the hull, propeller shaft, main sail and outboard engines to ensure that they are in working condition.

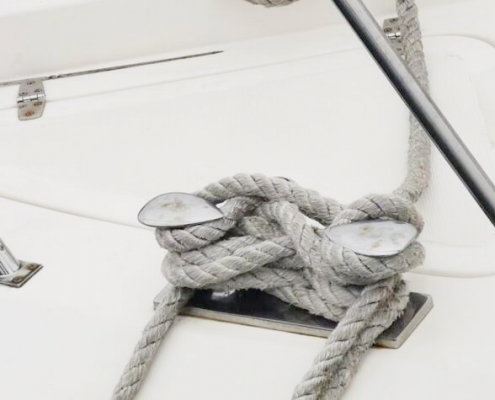

When you are checking your marine boat hardware, you have to remember that there are different types of hardware available in the market , each type has a different way of operating. So it is important to first determine the specific requirement of the equipment before buying them. This will help you choose the right equipment that best suits your boat’s requirements. The marine boat hardware also has the same quality and specifications to avoid the possibility of causing damage for the boat.

The marine boat hardware has to be well maintained in order to ensure that it is able to function properly. Thus, if you want to maintain the performance of the marine equipment, it is essential to buy quality marine boat hardware that will last for a long time. Also, it is also necessary to use the marine boat’s marine boat hardware to ensure that it works smoothly.