What is Precision Casting ?

Precision Casting is also known as lost wax. The method precision casting is cost-effective even at small series, thanks to a relatively low tooling cost ,and especially suitable for complicated components in materials such as steel, stainless, aluminum etc.

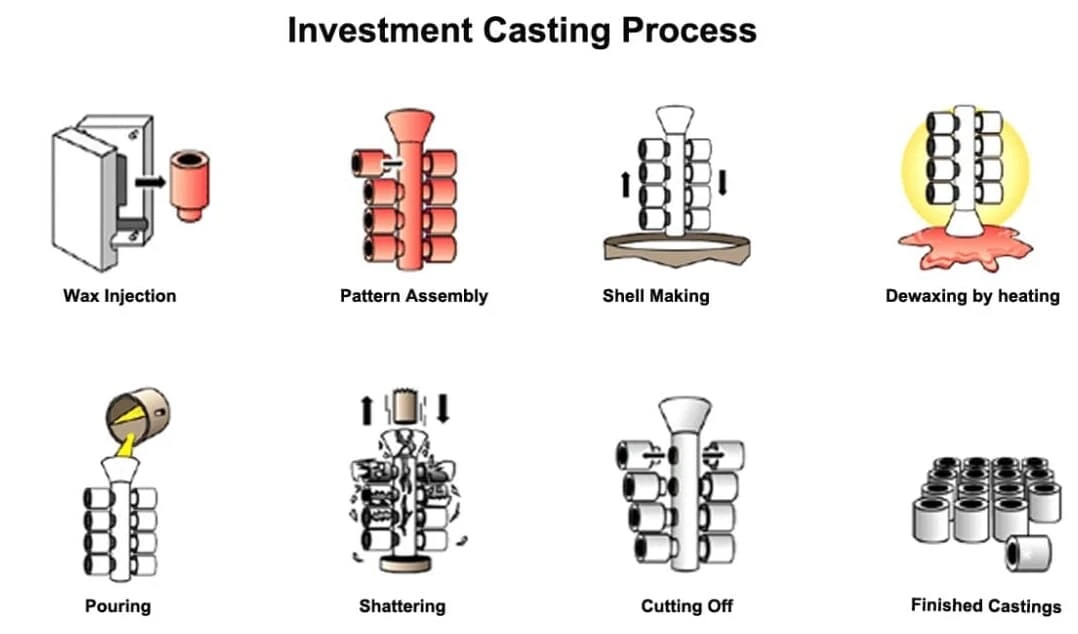

Process: A mould is manufactured in aluminum. A wax model is cast and assembled onto a tree which is covered by multiple layers of a special ceramic sand mixture. The ceramic mould is baked in an oven. After the wax is lost the ceramic mould is filled with any liquid metal. After cooling the ceramic mould is removed and the part is cleaned and processed.

Standard: ASTM, AISI, DIN, BS and JIS

Max Casting Size: 80CM

Casting Weight: 0.02~80Kg

Dimension Tolerance: CT5-CT7

Surface Roughness: Ra6.4~12.5