The Benefits of Using Stainless Steel Casting Parts

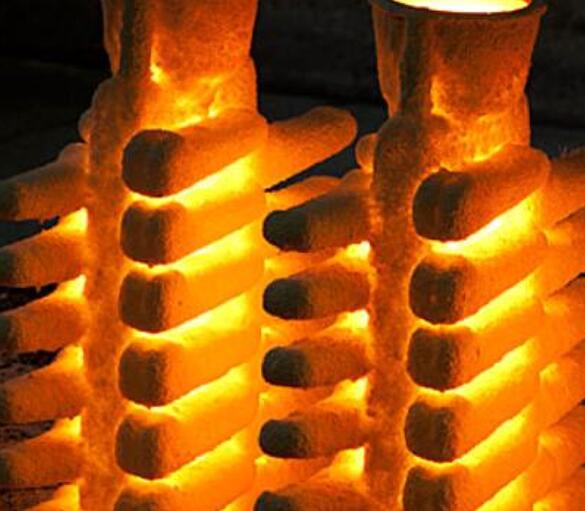

Stainless steel casting is a highly versatile and efficient technique widely used in various industries due to its numerous benefits. This process is renowned for its ability to produce parts and components with complex shapes, offering a higher level of design freedom compared to traditional machining methods. The adaptability of stainless steel casting allows for the creation of intricate designs, including components with complex details such as threads and undercuts, which are essential for precise fitting in various applications.

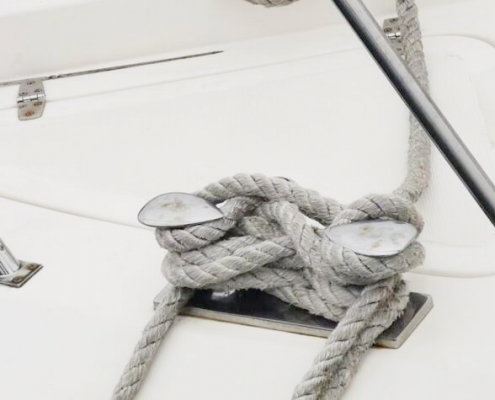

One of the key advantages of stainless steel casting is its exceptional corrosion resistance. This characteristic is particularly beneficial in industries where parts are exposed to corrosive environments, such as in marine, medical, automotive, and food processing applications. The corrosion resistance of stainless steel cast parts varies with the grade of the material used, with higher-grade materials offering greater resistance.

Stainless steel castings also exhibit high dimensional accuracy and precision, which is crucial for applications requiring components with exact specifications. This precision reduces or even eliminates the need for secondary machining processes, leading to cost savings and shorter production times. Furthermore, stainless steel’s resistance to high temperatures makes it suitable for use in applications like automotive engines, where components are regularly exposed to extreme heat.

The stainless steel casting process can be performed using various methods, including investment casting, sand casting, and die casting. Each of these methods has its own set of advantages, depending on the specific requirements of the project. Investment casting, for example, is known for producing parts with excellent surface finish and dimensional accuracy. In contrast, die casting is suitable for high-volume production of parts with uniform dimensions.

In terms of industrial applications, stainless steel casting is used in a wide range of sectors, including aerospace, architecture, nuclear, chemical, energy, construction, and automotive industries. The versatility of stainless steel casting makes it a preferred choice for manufacturing a diverse array of products, from small-scale components to large machinery parts.

Despite its numerous advantages, it’s important to note that stainless steel casting might require specialized equipment and expertise, potentially increasing costs or necessitating additional training for personnel involved in the process.

Overall, stainless steel casting offers a combination of corrosion resistance, precision, and versatility, making it a valuable technique for producing high-quality, durable parts across various industries.